Refresh. Reinvigorate. Revitalize.

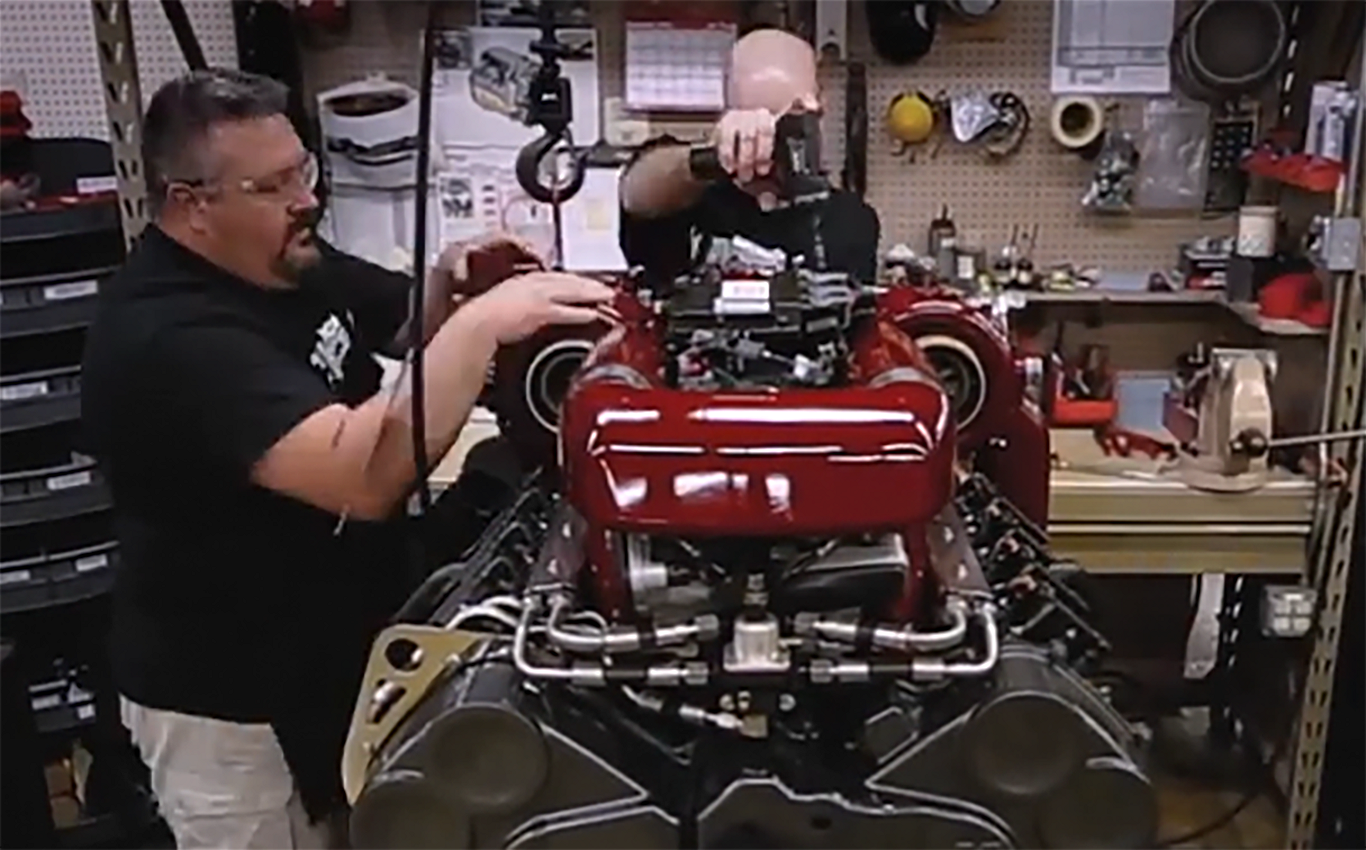

Mercury Racing technicians work their magic, starting with a bare cylinder block to build the QC4 core long blocks. The crankshaft and all other rotating components are washed and magnafluxed to ensure the metallurgy’s integrity. After the long-block assembly has been refreshed, it goes through Mercury Racing’s electrostatic, high-solid, polyurethane paint process to bring the engine back to like-new condition. Each engine endures a complete dynamometer run prior to being released and sealed as certified Factory Fresh. All parts purchased by the customer, including the long block, come with a Parts and Accessories Warranty that matches the original factory warranty.

QC4 Refresh

Retain the value and performance of your Mercury Racing QC4 engines with a complete factory refresh. The QC4 Refresh program features a thorough inspection and refresh of the engine by the same expert technicians who built it originally.

You made a significant investment in becoming one of an elite circle of owners with your purchase of Mercury Racing QC4v engines. The best way to protect your investment and ensure maximum reliability, durability, and performance from your QC4v product is by having the same technicians – the experts – who built your engines; perform the refresh right at the Mercury Racing factory. In addition, you can feel confident knowing all replacement components are genuine Mercury Racing factory original parts. Best of all, having your refresh work done at Mercury Racing means you receive a 1-year factory warranty on all replacement parts.

The Mercury Racing QC4 is one of the most proven, robust and durable high performance sterndrive engines on the planet. Even so, a QC4 engine runs under incredible stress, and will eventually require a factory refresh to ensure consistent performance and longevity. Unlike a maintenance procedure, which is constant based on hours of operation, the factory refresh does not have a specific set hour point for when a refresh is required. The reason for this is because the engine duty cycle and how the boat is operated may vary significantly from one owner to the next. A key indicator that your QC4 is due for a refresh is if you notice the boat is starting to feel a bit slower and the engine feels like it is not making as much power as it normally does. In addition, during the course of your regularly scheduled maintenance, if your dealer is no longer able to set the valve lash at the proper clearance, that’s a good indicator that you may be due for a refresh.

How you care for and operate your QC4 powered boat has a lot to do with the amount of time you will be able to run it before a refresh is needed. Many people believe high performance engines such as QC4s can take any level of use and abuse for an indefinite time. In reality, that’s only half true . . . the secret to long life and longer refresh intervals with QC4s is to use, but not abuse the powertrain. If you’ve just taken delivery of a brand new QC4 powered boat, the first thing to do is make sure you follow the instructions for the 25-hour break-in cycle. It is also imperative to never use fuel which has an octane value below the factory specification for a given QC4 model. To maximize your time on the water and your refresh intervals after that, make sure you have a qualified Mercury Racing dealer perform the prescribed maintenance religiously. True competition racers and avid hot rodders alike place great emphasis on reliability and durability, and they all have one thing in common. They take the time to really learn how to run the boat and the engines properly while squeezing out every last drop of performance. For example, they know that managing oil temperature is the key to long engine life. Some QC4 customers have literally gone hundreds of hours without a refresh just because they are paying attention to oil temperature. For example, one customer will start his engines and not run above idle speed until the oil temperature reaches 180 degrees F. After that, he’ll plane the boat off, but even then, he will not throttle up until the oil temp reaches 202 degrees and the thermostats have opened. When he comes off of plane, he will idle the engines until they cool to 194 degrees F, which may take several minutes. Taking steps like this, along with proper break-in and unwavering commitment to performing routine maintenance will deliver the longest possible intervals between factory refreshes.

All QC4v refreshes are processed through Mercury Racing dealer and boat builder partners. Simply contact your dealer or boat builder who will initiate the refresh authorization paperwork. Your dealer or boat builder will handle return shipment of your engines back to the Mercury Racing plant.

A typical QC4v refresh takes about 2 to 3 weeks from the time the engines arrive at Mercury Racing to the time they leave our plant.

A complete refresh takes about 145 man hours from start to finish with multiple Mercury Racing team members working throughout the process.

During a factory refresh, the following components are inspected and reused if they pass inspection: crankshaft, connecting rods, camshafts, finger followers, fuel injectors, exhaust manifolds & elbows, turbos, wire harness, charge air cooler, drive plate, all heat exchangers, air filters.

The following components are refreshed: dry sump pump, sea pump, cylinder block, cylinder heads.

Lastly, the folling components are replaced during a refresh. This list is not all inclusive: all seals, gaskets, belts & hoses, intake valves, exhaust valves, valve springs, spring retainers & keys, idler pulleys, main bearings, connecting rod bearings, pistons & rings, piston oil cooling jets, all timing chains & sprockets, timing chain guide shoes, coolant thermostat, oil thermostat.

Cylinder blocks are first cleaned ultrasonically. Cylinders are stripped and replated as needed. All cylinders are honed to ensure proper sizing and a good seat for the new piston rings. Long blocks also get a fresh coat of paint as part of this process.

During inspections, crankshafts and connecting rods are magnafluxed (a type of high tech x-ray) to ensure sound metallurgical integrity inside and out. In addition, exhaust logs and heat exchangers are inspected and pressure checked for leaks, and replaced at the customer’s expense if necessary. Finally, turbos are disassembled and inspected to ensure the integrity of the rotor bushings and blades.

Yes. The refresh includes a 2-hour run time on the dynamometer, which includes a break-in period and full power run. The valve lash is checked and all cylinders are inspected via bore scope prior to being approved for return shipment to the customer.

Yes. There is an option to have your QC4v transmission refreshed at Mercury Racing while your engine is at our location for its refresh. When you initiate the refresh process with your dealer or boat builder, please be sure to advise them at that time that you would like the transmission refreshed in addition to the engine itself.

We Never Settle